Resin sand casting

It is one of the widely used techniques.The molds often use resin based chemical binders that possess high

dimensional accuracy and high hardness.Such resin-bonded sand molds take somewhat longer to manufacture than green sand molds because a curing reaction must take place for the binder to become effective and allow formation of the mold. basically, such resin sand cast is for big parts objectively ,it's because the resin sand mould is much harder than green sand which can take bigger impact of much iron liquid.

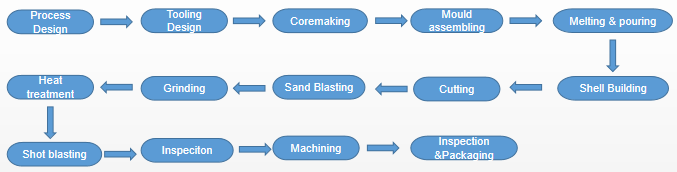

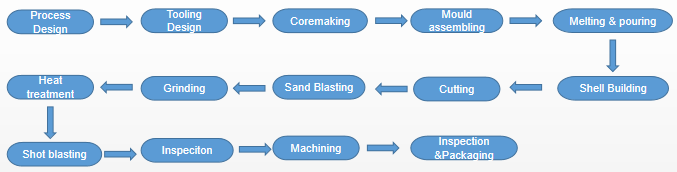

Process:

Material

Material:

Ductile iron, grey iron, Carbon steel,Alloy steel

Application Field: Automotive,Construction machinery,railway,Agriculture machining, Mining machinery,offshore

Single Unit Weight: 30kg-5ton/PC

Casting tolerance: ISO8062 CT12

Casting surface roughness: ≥Ra25um

Machining Capability:CNC

Heat Treatment:Solid solution, normalizing, annealing, quenching and carburizing

Surface treatment:Zinc plating, Hot-dip galvanization, Painting(wet pating, powder coating),Mirror polishing,Chrome plating

Contact us here for more information about VES

Contact:

Cellphone:+86(0) 180 1357 7772

Email:info@vescast.com

Tel: +86 180 1357 7772

Tel: +86 180 1357 7772

Email: jane.yang@vesmachinery.com

Email: jane.yang@vesmachinery.com